Anerobic, biological treatment

ALMA BHU GMR

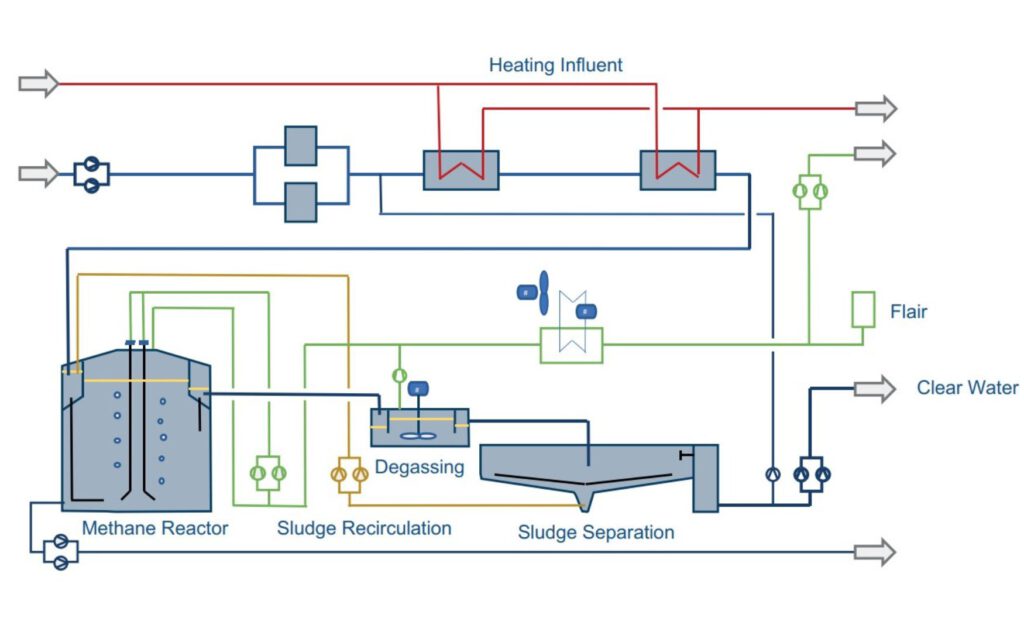

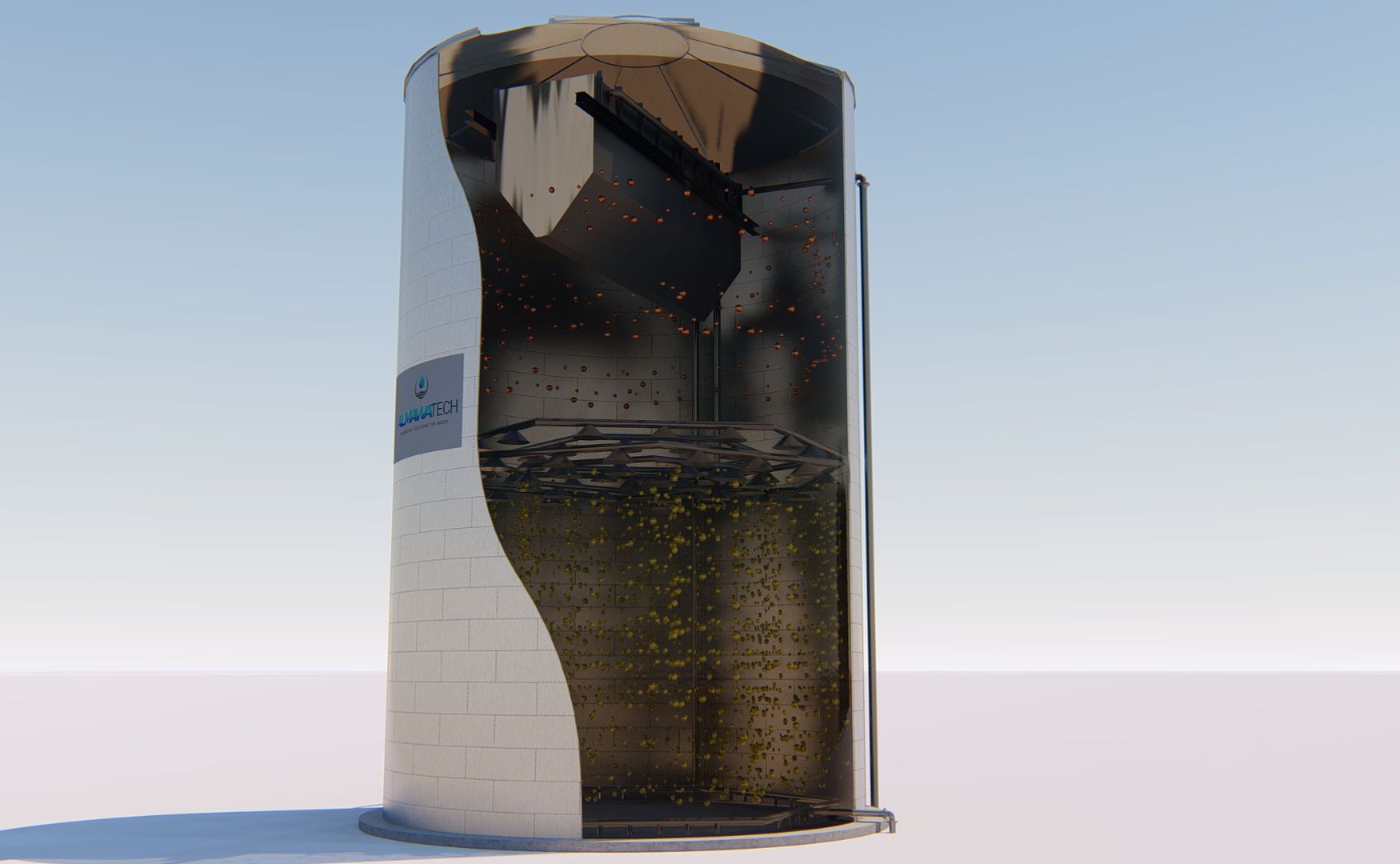

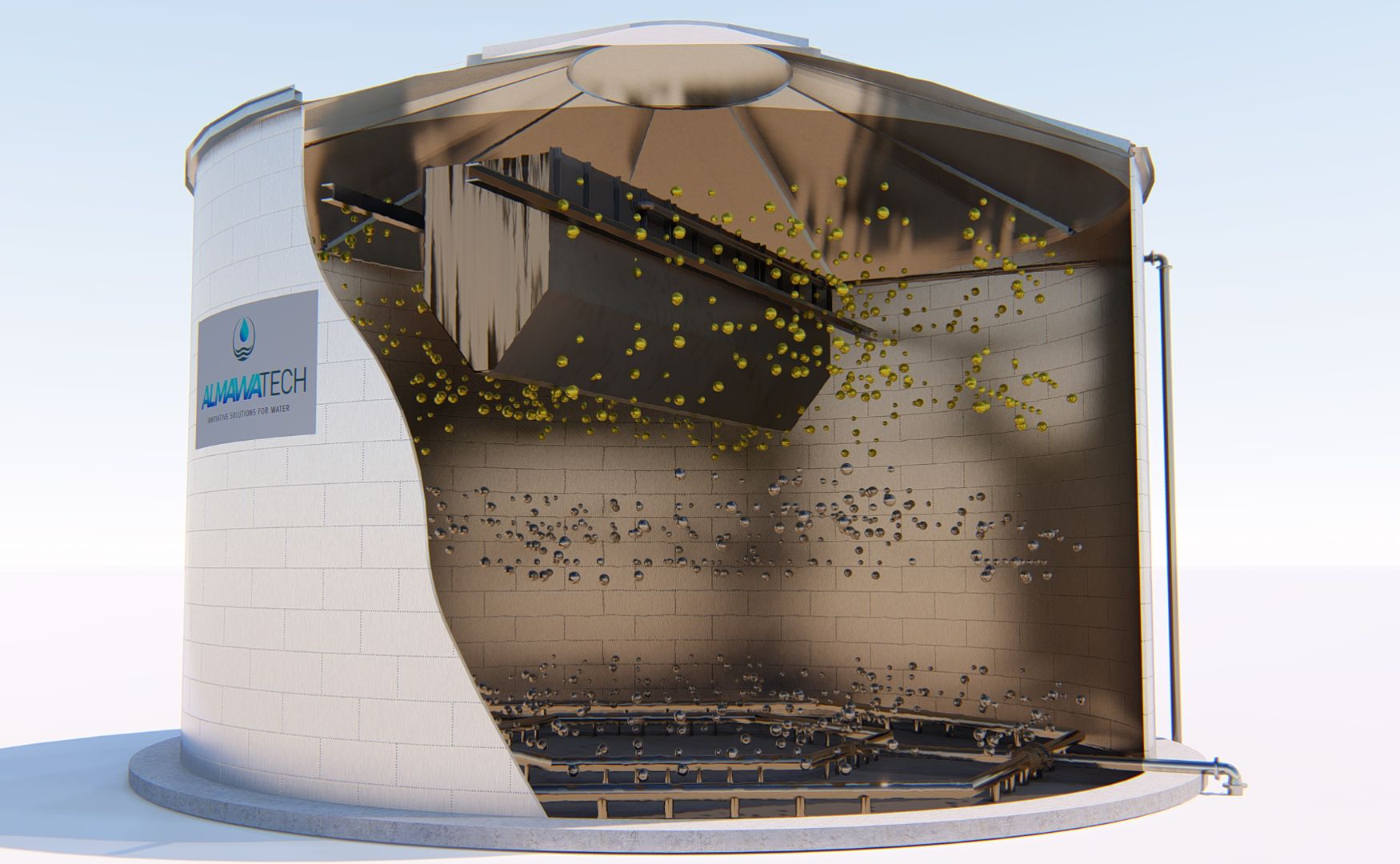

The ALMA BHU GMR (gas mixing reactor) is an innovative solution that has been specially developed to effectively ferment wastewater with increased calcium concentrations without causing increased deposits. This is achieved by cleverly using the generated and compressed biogas to circulate the reactor.

This innovative process also includes a downstream sedimentation tank that effectively returns the biomass to the anaerobic reactor. This targeted recirculation enables the biogas yield to be maximized and contributes to the overall efficiency of the ALMA BHU GMR.

Technical data

Main applications

Food industry Beverage industry Sugar industry Municipal wastewater

Hydraulic power

50 - 250 m³/h

COD room load:

9 - 19 kg COD / m³ / d

Get in touch with us!

We will be happy to help you if you have any questions about our ALMA BHU GMR.

Advantages

Particularly energy-saving design thanks to the efficient use of heat exchangers

Innovative circulation of the reactor through the recirculation of compressed biogas

The addition of compressed biogas makes it possible to ferment wastewater with increased calcium concentrations without significant crystal formation in the form of calcium carbonate.

Reactor made of enamel or stainless steel, depending on conditions. Piping normally in 1.4571

Process diagram: ALMA BHU GMR

Downloads

Tender text

Please contact our specialist for biogas plants: E-Mail

Similar products

ALMA BHU BIO EGSB

Two-stage anaerobic reactor ALMA BHU BIO EGSB, which can be fed with a high COD load due to the two-stage biogas extraction.

ALMA Biomage

The ALMA BIOMAGE system has been specially developed for the production of biogas from dairy and cheese dairy waste water. The system also features P precipitation.

ALMA BIO UASB

Single-stage anaerobic reactor ALMA UASB for the production of biogas from waste water from the food industry with reactor sizes up to 3,000 m³ and biomass recirculation.