Waste water and process water solutions

Toxic and harmful wastewater constituents often pose a major challenge in recycling processes and for waste disposal companies. These substances can come from a variety of sources, whether from chemical processes, the processing of hazardous materials or the handling of polluting substances. Specialized wastewater treatment processes are essential to address these risks and ensure compliance with strict environmental regulations.

Our products for the treatment of wastewater from the metalworking and electrical industries

ALMA OXI Fenton

Effective solution for the elimination of toxic and trace substances with hydrogen peroxide and iron salts.

ALMA NeoDAF HDED

The ALMA NeoDAF HDED is a dissolved air flotation system for wastewater flows of 12 - 120 m³/h.

ALMA Chem MCW

CP system for the elimination of heavy metals, solids and oils, including sludge treatment.

Take a look at a selection of our successfully implemented projects.

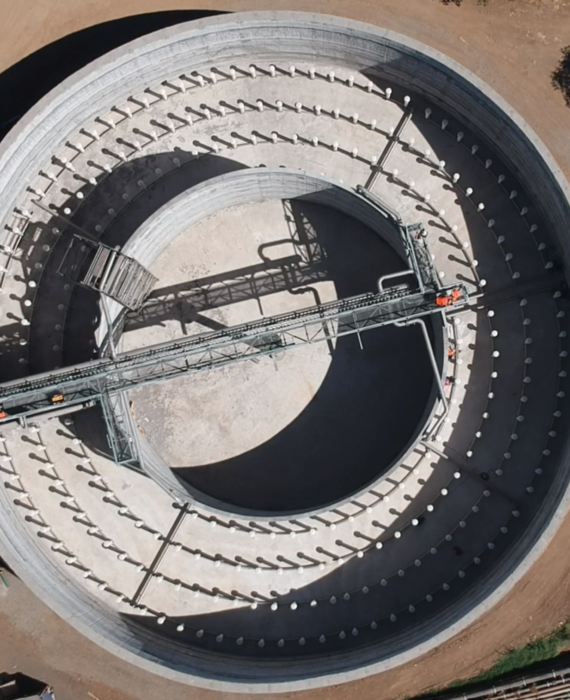

Sugar industry, Chile, ALMA BHU BIO

Construction of a biological treatment stage with sedimentation stage for the treatment of 120 m³/h of wastewater from the sugar industry in Pemuco, Chile.

3M, Germany, ALMA OSMO Process

Construction of a multi-stage pilot membrane plant for the removal of per- and polyfluorinated chemicals (PFAS) from wastewater with a hydraulic capacity of 1 m³/h for the company 3M.

REMONDIS Industrie Service, ALMA Chem MCW

A CP batch plant (ALMA CHEM MCW) with cyanide decontamination and gravel filtration for REMONDIS Industrie Service in Leuna.

Viterra, Magdeburg, ALMA NeoDAF HDED, ALMA FLOC AC

A wastewater treatment plant for production wastewater from biodiesel production with a capacity of 650 m³/d for the company Viterra Magdeburg GmbH.

TU Kaiserslautern, ALMA BIO, FENTON, UV, AK

Customized research plant in container design with coarse filtration, biological treatment, ultrafiltration, activated carbon filter, ozonation, hydrogen peroxide dosing and UV treatment for the TU Kaiserslautern.

German Aerospace Center, Germany, ALMA OSMO VE

Production of 750 liters of ultrapure water per day by means of softening, reverse osmosis and UV treatment from seawater for the German Aerospace Center (DLR).