Table of contents

Task

Vogtlandmilch GmbH can look back on over 80 years of tradition in the production of various high-quality dairy products in Plauen. The product portfolio includes a diverse selection, including UHT milk, fresh milk, butter and quark in various fat levels.

Due to the high pH value of the processed milk, it is necessary to neutralize it before it is discharged into the public sewer system. ALMAWATECH was entrusted with this challenging task in 2022.

Design data

The wastewater to be treated consists of rinsing water from production.

Waste water volume:

- max. 600 m³/d

Target parameters:

- Neutral pH value for discharge into the public sewer system

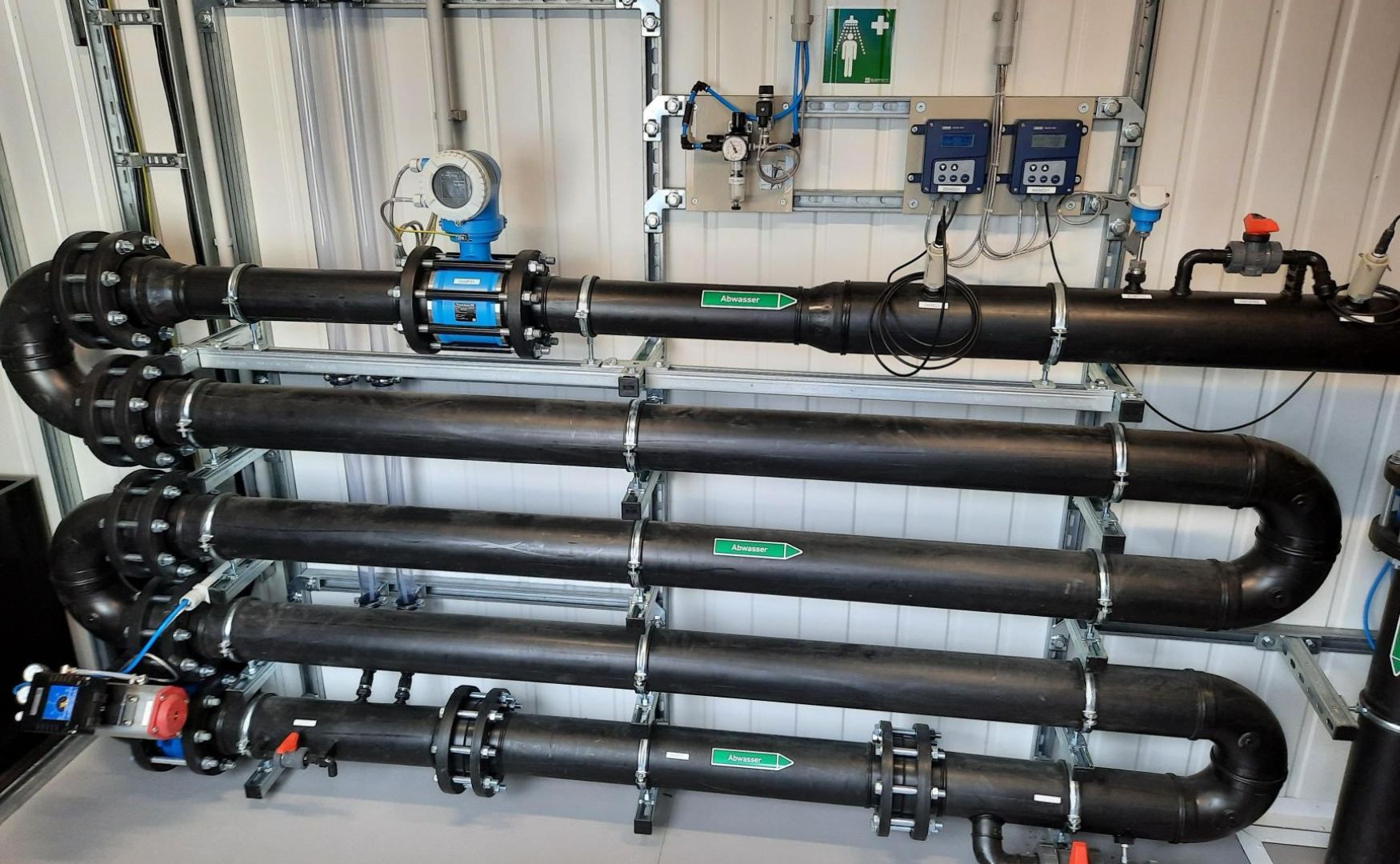

Our solution combines a mixing and equalizing tank (V = 215 m³), an NG 15 grease separator with a fail-safe double pumping station and an automatic neutralization system, known as ALMA Neutra. The precise coordination of these components ensures maximum efficiency and performance.

The neutralization system is installed together with the dosing station for the neutralization agent in an ALMA module. This system can be controlled in a user-friendly manner via the control cabinet with touch panel.

Impressions of the plant

Mixing and equalizing tank (V = 215 m³) with double pumping station and NG 15 grease separator (underground installation). In blue, the ALMA MODULE with automatic neutralization system.

Neutralization line with inline dosing and automatic pH control.

Automatic dosing station for operating fluids using diaphragm pumps.