Table of contents

Introduction to flotation technology

Photo: Our ALMA NeoDAF HDED (click here for the product)

Dissolved air flotation is an effective technology for removing various wastewater constituents such as COD, BOD, lipophilic substances, phosphorus, hydrocarbons and heavy metals from wastewater. In this article, we will give you an introduction to the process engineering basics and discuss the advantages and areas of application.

We will also be presenting our energy-efficient dissolved air flotation systems, the ALMA NeoDAF product range.

Process fundamentals of flotation plants

Functionality and principles of flotation technology

Dissolved air flotation is a physical separation process used in industrial wastewater treatment to eliminate undissolved and dissolved substances from wastewater.

The process begins with the conversion of dissolved substances such as hydrocarbons, dissolved metals, fats and COD into undissolved substances by means of so-called neutralization precipitation. For this purpose, specialized treatment agents (precipitants, neutralizing agents and flocculants) must be added to the wastewater before it enters the flotation cell. In our dissolved air flotation systems, this is done using a patented control system and online COD measurement. This leads to considerable savings in operating resources compared to other commercially available dissolved air flotation systems.

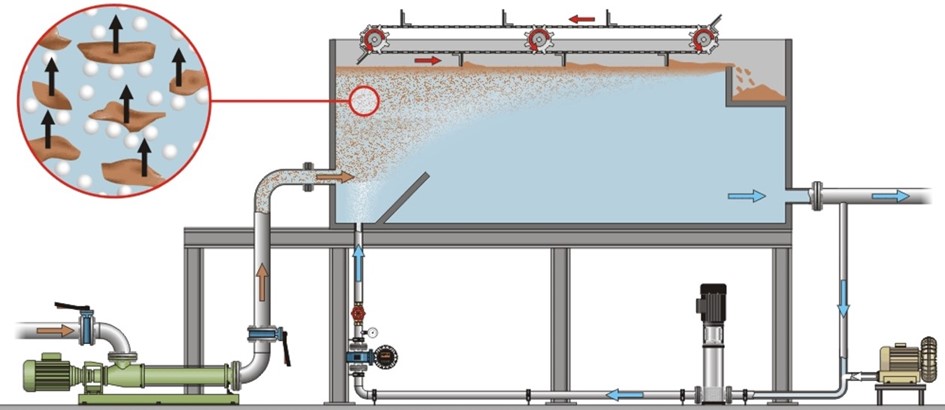

The wastewater stream with the precipitated (undissolved) substances then enters the flotation cell. As can be seen in the illustration above, a second water flow is introduced shortly after the inlet of the flotation cell. This consists of treated clear water that has been saturated with air at an overpressure of 4 - 6 bar.

When the partial flow saturated with air arrives, excess air bubbles up in the form of microbubbles. These enclose the undissolved substances in the wastewater and allow them to rise to the surface, creating a flotate sludge. This sludge carpet can then be separated using our scraper system. The following illustration shows the so-called flotate sludge at one of our NeoDAF systems.

A decisive success factor in the operation of flotation plants is the precise control of the treatment agents. The selection of suitable precipitants and flocculants as well as the dosage have a significant influence on cleaning efficiency. Overdosing leads to costly operation, while underdosing impairs compliance with the cleaning targets.

In addition to the chemical dosage, the size of the gas bubbles also plays an important role. Bubbles that are too large lead to a slower ascent rate and thus to reduced adhesion to the undissolved pollutants in the wastewater. Bubbles that are too small, on the other hand, can lead to overlaying and thus impair the formation of the flotate sludge.

The optimum size of the gas bubbles is in the range between 60 and 80 µm. pH value, saturation pressure, flow velocity and water composition are decisive factors influencing the bubble size. Experience in the construction and operation of dissolved air flotation systems and special inlet valves in the inlet area are required to ensure the optimum gas bubble size.

Treatment chemicals in flotation technology

Photo: ALMAFloc APH, precipitant for flotation plants (Product overview of precipitants)

The selection of treatment agents and precise dosing are crucial for the efficient operation of flotation systems. There are a variety of treatment agents that can be used depending on the type and quantity of impurities. As a rule, a combination of three different treatment agents is used: Precipitants, neutralizing agents and flocculants, also known as polymers.

Precipitants such as iron(III) chloride (e.g. ALMA FLOC FE40) are used to promote the formation of effective flocs and bind pollutants. The resulting microflocs are often so small that they are barely visible to the naked eye.

The addition of neutralizing agents such as caustic soda causes these microflakes to grow. This occurs due to the hydroxide group of the neutralizing agent. The negatively charged hydroxide groups bind various pollutants together, which leads to an increase in the microflakes. Due to the change in the pH value and thus the solubility limit, the contaminants are now present as undissolved solids.

In order to produce a larger sludge floc in the final step, flocculants are added. These long-chain polymers, consisting of carbon chains with different charges, are divided into cationic (positively charged) and anionic (negatively charged) flocculants. These bind the previously formed flocs together to form larger sludge flocs.

The choice of the optimum precipitants, neutralizing agents and flocculants depends on the concentration and type of impurities as well as the cleaning objectives. For a precise determination, you should always consult an expert and send in a wastewater sample for laboratory tests.

Areas of application for flotation systems

Possible applications in various industries

Photo: Our compact flotation system ALMA NeoDAF Blue

In the food industry, dissolved air flotation systems are used to remove fats and oils and therefore COD, lipophilic substances, BOD, nitrogen and phosphorus. Typical industries are dairies, vegetable and fruit processing and food processing. Dissolved air flotation is also used in the purification of wastewater from meat and poultry processing to remove blood, fat and other impurities.

In the pulp and paper industry, flotation is often used to remove colorants from wastewater. Due to their low density, these impurities cannot simply be removed by sedimentation and must therefore be removed by dissolved air flotation.

Other typical industries in which dissolved air flotation is frequently used are

- in wood processing,

- in scrap yards,

- in the chemical and pharmaceutical industry,

- in metal processing,

- in the petrochemical industry,

- in the cosmetics industry

- and in plastics processing.

Potential application challenges and how to solve them

Various challenges can arise when using dissolved air flotation to treat industrial wastewater. Here are some of the potential challenges and possible solutions.

- Variability of the wastewater composition:

One problem in the operation of dissolved air flotation is the variability of the wastewater composition, particularly in the case of wastewater from the food industry or the chemical industry. The composition of the wastewater can change significantly during ongoing production operations.

To solve this problem, operators should carry out regular wastewater analyses to monitor the composition of the wastewater. The results of these analyses can be used to optimize the dosing of treatment agents. In our ALMA NeoDAF series dissolved air flotation systems, this is done by a patented control system in combination with online COD measurement. This enables precise dosing of the treatment agents and therefore considerable cost savings.

- Difficulties in removing high-density particles:

Another problem in the operation of dissolved air flotation systems is the removal of high-density particles such as sand or metal salts.

To solve this problem, the flotation system can be combined with other separation processes such as sedimentation or filtration. Another option is to use special treatment agents that are optimized for the removal of high-density particles.

- Clogging of the flotation plant:

Another problem with the use of flotation is the clogging of the flotation plant by flotate sludge, particularly in the case of wastewater with a high solids content.

To solve this problem, special devices can be installed to intercept and remove the flotation sludge before it clogs the flotation system. Regular maintenance of the flotation system can also help to prevent blockages.

Advantages of flotation systems

Flotation plants have proven to be extremely effective in industrial wastewater treatment and offer a variety of benefits. In this section we will explain some of the key benefits of flotation plants.

- High cleaning efficiency:

Flotation plants can achieve high purification efficiency and remove a wide range of contaminants from wastewater. The flotation process can even eliminate very fine and difficult-to-separate particles of just a few micrometers.

- Space-saving:

Compared to other cleaning technologies, flotation systems require little space. This means they can be installed in systems where space is limited.

- Low maintenance effort:

Flotation systems are very reliable and fail-safe in operation. The maintenance requirements of a dissolved air flotation system are also relatively low. This results in low operating costs and short downtimes.

- Wide range of applications:

Our dissolved air flotation systems can be used in various industries, such as the food and beverage industry, the chemical and petrochemical industry, the paper industry and the textile industry.

- Environmental friendliness:

Our dissolved air flotations are characterized by a bubble booster system developed in-house, which makes them more energy-efficient than conventional dissolved air flotations.

Conclusion

Industrial wastewater treatment is an important process for companies. It is crucial that this wastewater is treated carefully and cost-effectively in order to comply with legal requirements.

An important factor in the treatment of industrial wastewater is knowing the exact composition of the wastewater. Every industry produces different types of wastewater, which may contain different contaminants. It is therefore important to select the right technology and the right treatment process to achieve an effective result.

If you need more information or assistance with industrial wastewater treatment, contact our experts. We offer a wide range of wastewater treatment solutions and can help you find an effective and sustainable treatment solution for your business. Feel free to contact us at any time!

To the product overview of our own developed dissolved air flotation systems.