Task

Treatment of river water for a leading global manufacturer of recycled fiber-based pulp, paper, corrugated board and corrugated cardboard.

Design data

Waste water volume:

- 800 m³/h

Target parameters:

- Use as process water for production and as cleaning water.

Solution & implementation

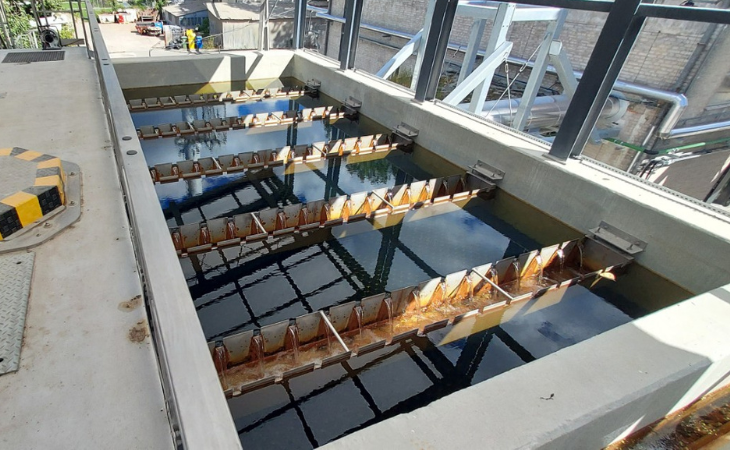

We use our CP system ALMA BHU LHPS process for the efficient removal of dissolved phosphorus and nitrogen compounds as well as undissolved particulate matter from river water.

The ALMA BHU LHPS process is based on the principle of precipitation and flocculation, followed by separation of the sludge flocs. The high-performance settlers are equipped with specially developed honeycomb-shaped lamellas that offer an exceptionally large specific surface area. This not only reduces the space required

References Paper production & river water treatment

Similar projects

Similar projects

Paper mill, Southern Germany, ALMA BHU BAF

Construction of a third treatment stage for wastewater from paper and corrugated cardboard production with a capacity of 700 m³/h for a leading European manufacturer in southern Germany.

Paper mill, Poland, ALMA BHU LHPS

River water treatment plant with a capacity of 800 m³/h for a leading global manufacturer of paper, corrugated board and corrugated cardboard in Poland.

Walki Ekopak S.A., ALMA CHEM MCW, ALMA FIL

Treatment of 4m3 of wastewater per day from the printing of packaging using the flexographic printing process. Wastewater treatment using a precipitation/flocculation plant and final filtration for Walki Ekopak S.A.