Task

Construction of an anaerobic wastewater treatment plant for the production of biogas from sugar production wastewater.

Design data

Waste water volume:

- 125 m³/h

Solution & implementation

Our innovative process for producing biogas from beet wash water with a high sugar content is characterized by four key process steps.

- Pre-acidification of the beet wash water: The first step is to pre-acidify the sugar-rich beet wash water. This forms the basis for the efficient process.

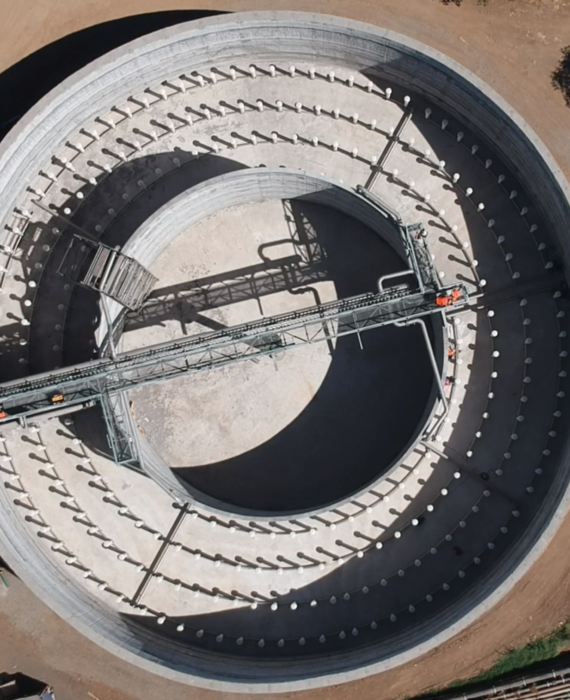

- Special ALMA BHU GMR - insensitive to calcium: In the second step, the pre-acidified beet wash water enters our specially developed ALMA BHU GMR (gas mixing reactor). This reactor was specially designed for wastewater with high calcium concentrations and is characterized by its robust design and mode of operation, which is insensitive to calcium deposits.

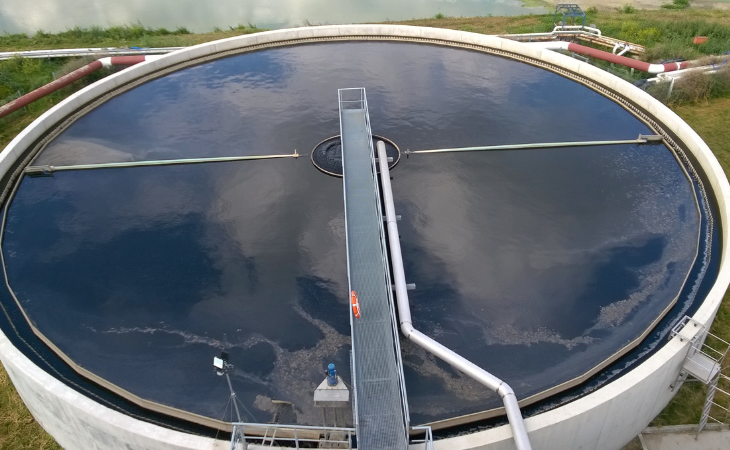

- Optimization through biomass recirculation: The biomass is separated and partially recirculated in a downstream sludge thickener. This not only leads to an increased biogas yield, but also enables more efficient mixing of the reactor.

- Biogas treatment and utilization: The biogas obtained undergoes thorough drying and desulphurization. We have also installed a biogas flare and heat exchangers. The heat exchangers ensure a constant temperature of 37 °C in the biogas reactor in order to provide the methanogenic bacteria with optimum conditions for the efficient conversion of the COD.

References sugar industry

Biogas production

Similar projects

Eisbär Eis GmbH, Germany, ALMA NeoDAF HDED

We had the opportunity to supply and install our ALMA NeoDAF flotation system with a capacity of 16 m³/h as part of the construction of a new wastewater treatment plant for an ice cream manufacturer in northern Germany.

Sugar industry, Chile, ALMA BHU BIO

Construction of a biological treatment stage with sedimentation stage for the treatment of 120 m³/h of wastewater from the sugar industry in Pemuco, Chile.

Sugar factory, Germany, ALMA BHU GMR

Construction of an anaerobic treatment stage or biogas plant for the recovery of energy from waste water from a sugar factory with a hydraulic capacity of 220 m³/h in Germany.

Sugar factory, Poland, ALMA BHU GMR

Construction of an anaerobic treatment stage and a biogas plant to generate energy from sugar production wastewater with a hydraulic capacity of 125 m³/h in Poland.

Sternquell Brauerei GmbH, ALMA Neutra

Treatment of 360m3 of brewery wastewater per day with a pump shaft, solids separator and a neutralization system for Sternquell Brauerei GmbH.

Bäckerei Betz GmbH, Germany, ALMA NeoDAF Blue, grease separator

Treatment of 25m3 of bakery wastewater per day in a grease separator and a flotation plant for Bäckerei Betz GmbH.

Südzucker AG, Ochsenfurt, ALMA BHU GMR, BIO

Treatment of sugar beet wash water in a biogas plant with pre-acidification and a COD load of 45,000 kg COD/d, for Südzucker in Ochsenfurt.

Schweizer Zucker AG, Switzerland, degasser

A deaerator for a biogas plant between the lime separator and circular clarifier for Schweizer Zucker AG at the Frauenfeld site in Switzerland.

Südzucker AG, Belgium, ALMA BHU BiosS-Treat

A river water treatment plant (2 x 275 m³/h) for the production of process water, cooling water and boiler feed water in drinking water quality with reverse osmosis system and ion exchangers for the company Südzucker AG at the Wanze site in Belgium.

Südzucker Zeitz PWT

A river water treatment plant with a capacity of 220 m³/h using the ALMA BiosS-Treat processfor Südzucker AG at the Zeitz site.