The chemical treatment of cooling water systems is essential for the efficiency and longevity of the systems. Problems such as limescale deposits, corrosion, sludge formation and microbiological growth can significantly impair the functionality of cooling systems and even lead to expensive downtime. There is also a risk of pathogenic microorganisms such as legionella spreading in the cooling water. These problems can be prevented by professional cooling water treatment.

Table of contents

Aim of the chemical treatment of cooling water systems

Protection against corrosion

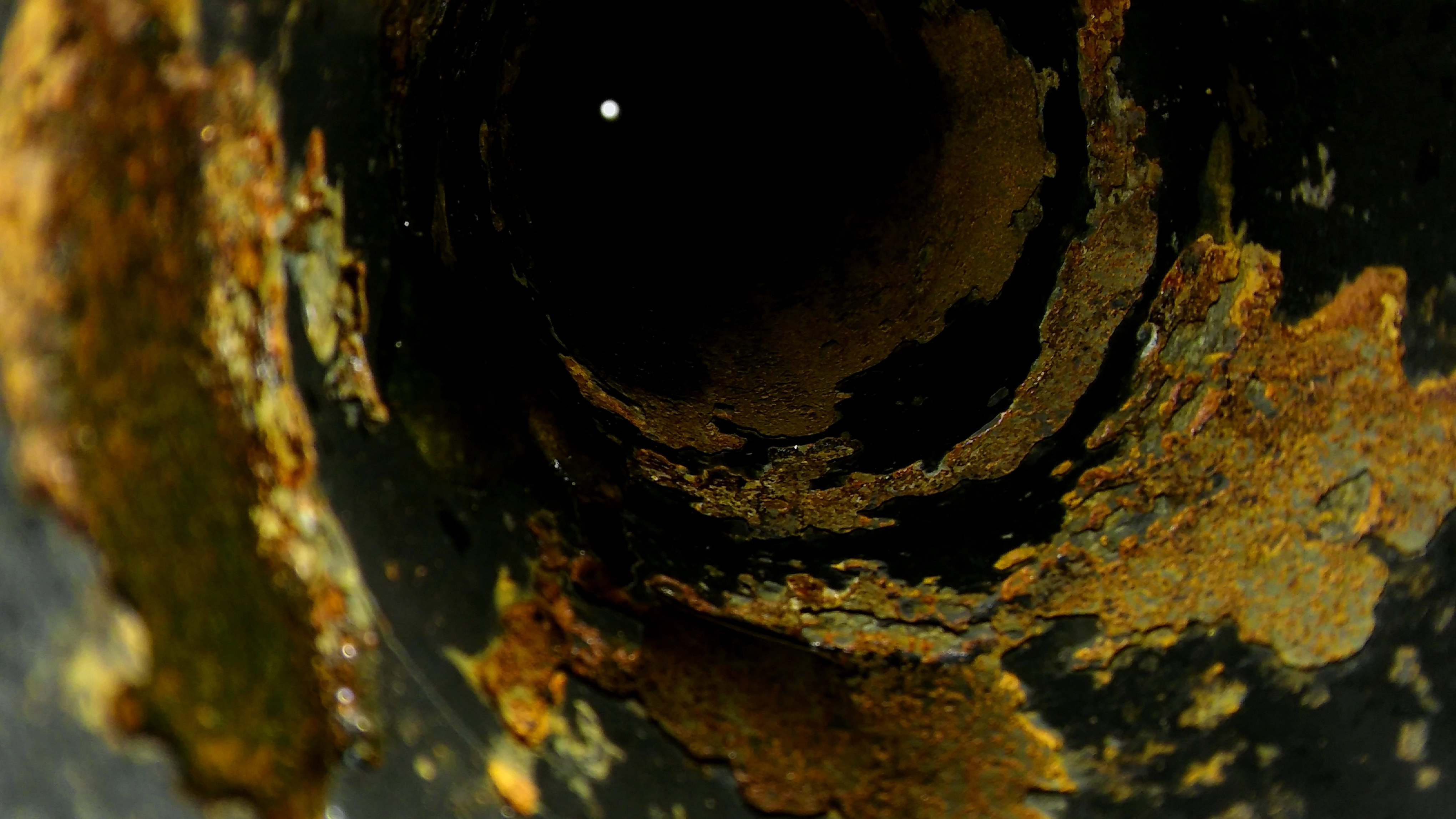

Corrosion is a key challenge in cooling systems. Corrosive elements such as oxygen and dissolved salts attack metal surfaces and cause damage. Our corrosion protection chemicals form a protective layer on the metal surfaces and thus prevent oxidation, extending the service life of the systems.

Photo: Corrosion in a pipe of a cooling circuit

Avoidance of deposits

Limescale and other deposits impair heat transfer in cooling systems. Hardness stabilizers prevent the formation of such deposits, while dispersants help to keep suspended solids in suspension and prevent them from precipitating.

Photo: Deposits and biological growth in an open cooling system

Optimization of water quality

Controlled water quality is crucial for the smooth operation of cooling systems. Chemical treatments ensure that the water has the right properties, including controlling residual hardness, regulating pH and removing dissolved gases.

Increased efficiency

Clean, optimally treated water ensures excellent heat transfer and increases the energy efficiency of the cooling systems. This leads to lower operating costs and more sustainable operation. A professional calculation of a cooling tower or evaporative cooling system can ensure smooth operation.

Avoidance of operational failures

Regular chemical treatments minimize the risk of malfunctions and breakdowns. Continuous monitoring and adjustment of the chemical supply ensures stable and reliable operation of the systems.

Compliance with legal requirements

Compliance with legal regulations and industry standards is another goal of chemical water treatment. Professional water treatment programs help to meet these requirements and avoid legal problems.

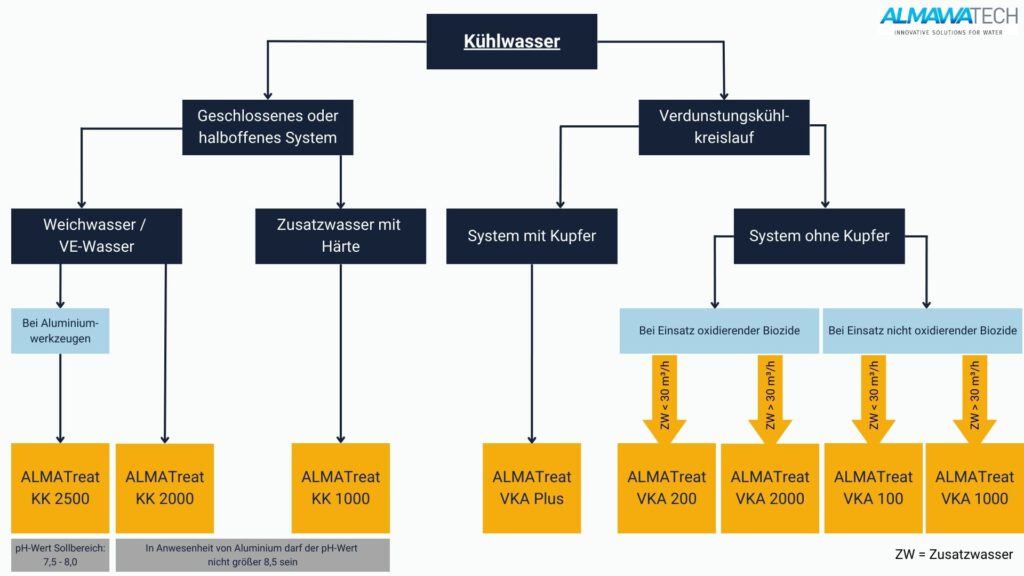

The different product groups for the treatment of cooling water

Photo: Here you will find a rough overview of our equipment for cooling systems as well as a guide to subdividing the product groups according to application and task.

Corrosion inhibitors

Corrosion inhibitors form a protective layer on the metal surfaces and prevent oxidation. Typical corrosion inhibitors include phosphates, silicates and organic inhibitors. These chemicals extend the service life of the systems and protect against corrosion damage.

Hardness stabilizers against limescale

Our highly effective hardness stabilizers prevent the build-up of salts in the cooling system. They are used in both open and closed cooling circuits to prevent or reduce the loss of calcium carbonate.

Dispersing agent

Dispersants help to prevent the formation of deposits by keeping suspended solids in suspension and preventing them from precipitating. They contribute to the cleanliness and efficiency of the systems by removing existing deposits and preventing new ones from forming.

Bio-dispersants against biofilms

Biocides often reach their limits with stubborn soiling. Bio-dispersants dissolve the layers of slime in which microorganisms form and multiply. This is particularly important in the case of elevated legionella levels to ensure rapid and effective control.

Biocides against microbiology

Our biocide products are effective against microorganisms such as bacteria, legionella, germs, algae and fungi. They are also effective at low doses and are particularly effective at removing biofilms. For optimum protection, biocides should be selected and dosed correctly.

Photo: Limescale deposits and a heavy biofilm on the heat transfer surfaces. These can be avoided by using adapted biocides and bio-dispersants.

Types of cooling towers and their treatment

Wet cooling towers

Wet cooling towers, also known as evaporative cooling towers, use the evaporation of water to dissipate heat. Water quality is particularly important here in order to avoid deposits and corrosion. Corrosion inhibitors, hardness stabilizers and biocides are crucial to ensure efficient and safe operation.

Photo: Wet cooling tower

Dry cooling towers

Dry cooling towers use air for cooling and avoid direct contact between water and air. Although they are less susceptible to biological contamination, they can still have corrosion problems. Special corrosion inhibitors are necessary here to protect the metal components.

Hybrid cooling towers

Hybrid cooling towers combine the advantages of wet and dry cooling towers. They use both air and evaporative cooling, which enables flexible adaptation to different operating conditions. The chemical treatment must be carefully coordinated to prevent both corrosion and biological contamination.

Photo: Hybrid cooling tower

Treatment of various cooling circuits

Open cooling circuits

Open cooling circuits are directly exposed to the ambient air, which leads to evaporation losses and concentration of impurities. These systems require intensive chemical treatment to prevent deposits and biological contamination. Hardness stabilizers, dispersants and biocides are essential here.

Closed cooling circuits

Closed cooling circuits have no direct contact with the ambient air, which makes them less susceptible to contamination. Nevertheless, corrosion and deposits can occur. Corrosion inhibitors and dispersants are the main components of chemical treatment to maintain system efficiency.

Evaporative cooling systems

Evaporative cooling systems use evaporation for cooling and are therefore particularly susceptible to limescale deposits and biological contamination. A combination of hardness stabilizers, biocides and dispersants is necessary to overcome these challenges and ensure the efficiency of the system.

Photo: Evaporative cooling system

Summary and objectives

The chemical treatment of cooling water systems is essential for their efficient and trouble-free operation. Corrosion inhibitors, hardness stabilizers, dispersants and biocides play a central role here. They protect against corrosion, prevent deposits and optimize water quality. The correct use of these chemicals can significantly increase the service life and efficiency of your cooling water system.

Our aim is to make the operation of your cooling water system as efficient and smooth as possible. Find out more about our comprehensive solutions and how they can help you maximize the performance and service life of your cooling systems. We will be happy to provide you with customized advice and optimal dosing solutions.

Our ALMA AQUA product range - Efficient operating fluids for cooling circuits

Free consultation appointments

Arrange an online consultation with our cooling water treatment specialist.