The monitoring and control of cooling water systems plays a crucial role in maximizing the efficiency of systems while at the same time meeting legal requirements. The ALMA Trol Std Assembly offers an innovative solution that is characterized by its compact design, comprehensive control functions and high adaptability. This solution is specifically designed to efficiently monitor cooling circuits, optimize operation and simplify reporting in accordance with VDI 2047 Sheet 2 and the 42nd BImSchV.

Table of contents

The importance of cooling water monitoring

Cooling water systems, especially in industrial applications, must work reliably in order to prevent the systems from overheating and at the same time keep the environmental impact as low as possible. Compliance with legal requirements, such as VDI 2047 Sheet 2 (Hygienic requirements for evaporative cooling systems) and the 42nd BImSchV (Federal Immission Control Ordinance), is essential. Cooling water monitoring systems not only help to comply with these regulations, but also increase operational safety by providing early warning of faults and enabling preventative measures to be taken.

The ALMA Trol Std Assembly goes one step further here: it automates the monitoring and control of the cooling water and provides immediate warnings in the event of faults thanks to the integrated email notification function. This allows potential problems to be detected and rectified at an early stage before damage occurs.

Photo: ALMA Trol Std Assembly for cooling water monitoring and control

Main functions of the ALMA Trol Std Assembly

The ALMA Trol Std Assembly is characterized by a large number of functions that are specially tailored to the requirements of cooling water systems. These functions make a significant contribution to making operation safer, more efficient and more cost-effective.

1. conductivity-controlled desalination

The continuous monitoring of conductivity automatically controls the desalination of the cooling water. This ensures efficient use of the water and prevents excess concentrations of salts, which increases operational safety and extends the service life of the systems.

2. biocide dosing with interlock and pre-salting

To control microbiological growth in the cooling circuits, the ALMA Trol Std Assembly offers precise dosing of biocides. The interlock function prevents overdosing and pre-salting enables unwanted substances to be removed before the biocide is added.

3. product content measurement via ALMA Treat and tracer technology

With the help of ALMA Treat equipment, the content of products in the cooling water can be monitored and controlled. This enables precise control of the chemicals used and ensures the resource-saving use of treatment products.

4. ORP measurement for efficiency control of oxidizing biocides

The efficiency of oxidizing biocides such as chlorine or ozone is monitored via ORP measurement (redox potential). This ensures that the biocides used have an optimum effect and that the cooling water flow is hygienically perfect.

5. pH value measurement and control options

Precise pH control is crucial for preventing corrosion and deposits in the cooling circuits. The ALMA Trol Std Assembly enables continuous monitoring and control of the pH value to maintain the chemical balance in the system.

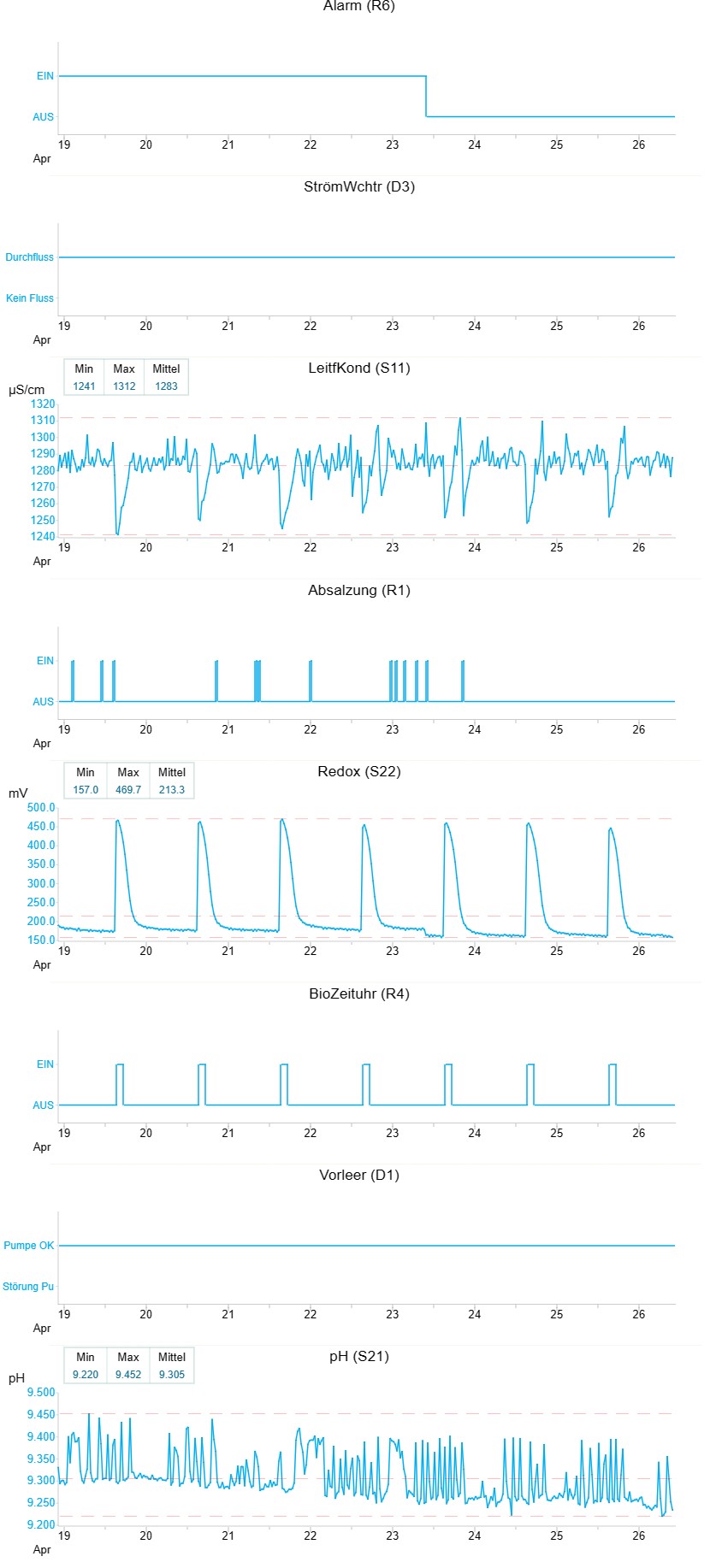

6. data logging and alarm communication

All recorded parameters are automatically stored for up to three months and can be retrieved as required. Alarms and measured values can be sent by email to up to eight recipients, making reporting and management of the cooling water systems much easier.

Illustration: Example of a weekly report from the ALMA Trol Assembly

Additional options for even more flexibility

In addition to the main functions mentioned above, the ALMA Trol Std Assembly offers various expansion options to meet the specific requirements of customers even better:

Corrosion measurement according to DIN 50905

This function can be used to monitor copper and black steel pipes in order todetect and preventcorrosion at an early stage.

Remote maintenance mode

The remote maintenance function makes it easy to monitor and control the system remotely, which is particularly advantageous for large systems or multiple locations.

MODBUS capability

The ALMA Trol Std Assembly can be integrated into existing network structures via the MODBUS interface. This enables seamless communication with other systems and central monitoring.

Advantages for the customer

The ALMA Trol Std Assembly offers numerous advantages for operators of cooling circuits. In addition to improved operational reliability thanks to automatic monitoring and control, existing systems can also be retrofitted cost-effectively. The compact design enables easy installation, and the comprehensive monitoring functions ensure that the system is operated optimally at all times.

In addition, compliance with VDI 2047 Sheet 2 and the 42nd BImSchV not only contributes to operational safety, but also helps to fulfill legal requirements and avoid possible sanctions.

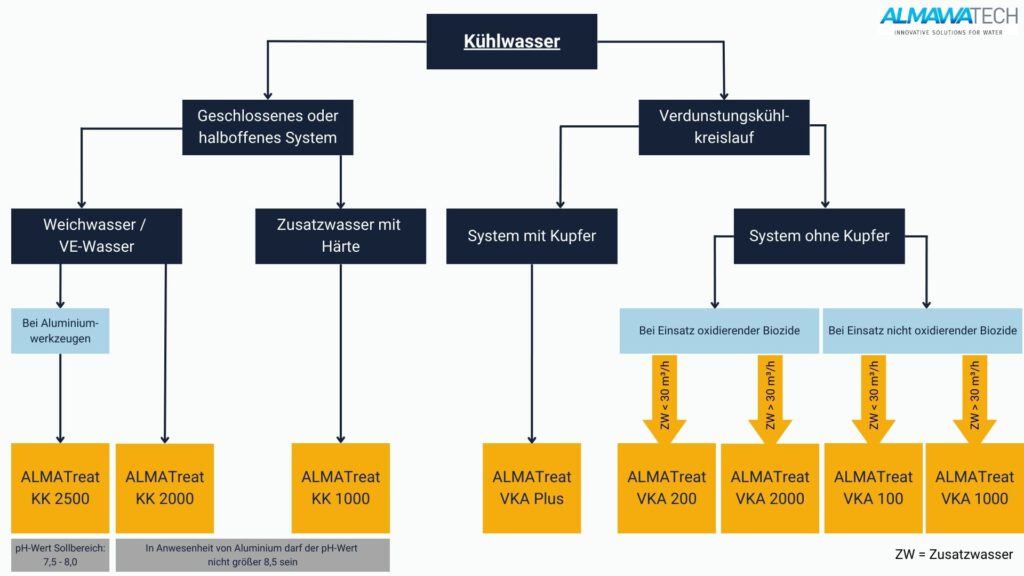

Operating fluid for cooling water treatment

In addition to monitoring and controlling cooling water systems, our expertise in cooling water treatment offers a tailor-made solution for optimizing your system. By professionally conditioning the cooling water - whether for cooling towers, closed or semi-open cooling circuits - we ensure trouble-free operation and protect your system against corrosion, deposits, microbial contamination and legionella formation.

Our ALMA AQUA product range - Efficient operating fluids for cooling circuits

Our resources include:

- Corrosion protection: Prevents corrosion on the system components and extends their service life.

- Hardness stabilizers: Protects against deposits of limescale and other minerals.

- Dispersants: Keep suspended solids in suspension and prevent deposits.

- Biocides: Protect against microbial contamination and prevent the growth of legionella and other harmful microorganisms.

Illustration: Here you will find a rough overview of our equipment for cooling systems as well as a guide to subdividing the product groups according to application and task.

Thanks to our many years of experience and the specialist knowledge of our employees, we create individual treatment plans for you that are tailored to the specific requirements of your system. This not only ensures optimum protection for your systems, but also reduces operating costs by avoiding malfunctions and breakdowns.

Click here for an overview of our operating fluids for cooling circuits: ALMA AQUA - Cooling water treatment.

Conclusion

With the ALMA Trol Std Assembly provides operators of cooling water systems with a powerful and flexible solution for monitoring and controlling their systems. With its numerous functions and expansion options, the system offers a tailor-made solution for any system, regardless of its size or complexity. In addition, data logging and alarm communication enable simple and efficient reporting, which significantly reduces administrative work.

Learn more about the ALMA Trol Std Assembly and how it can help you optimize your cooling water systems while protecting the environment. Visit our blog to dive deeper into the technical details and find out how this technology can improve your system.

Further information: Efficient cooling water treatment

Are you interested in more information about cooling water treatment and challenges such as deposits, corrosion and microbial growth? In our blog article "Efficient cooling water treatment: what to do about deposits, corrosion, biological growth and legionella", you can find out all about proven measures to avoid these problems. Take a look to delve deeper into the topic and discover the best solutions for your system.

Free consultation appointments

Arrange an online consultation with our cooling water treatment specialist.